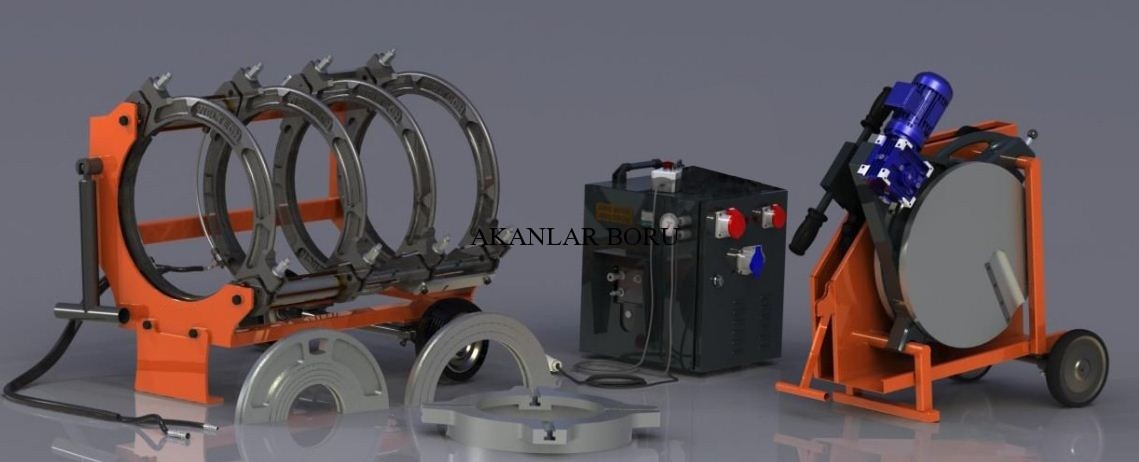

HDPE 100 PIPE BUTT WELDING MACHINES Sales & Leasing and application-SERVICE MAINTENANCE

HDPE 100 pipe butt welding machines for sale:

BUTT WELDING MACHINE Sales & Leasing and application-SERVICE MAINTENANCE

Butt Welding Machines diameters up to 20 mm to 2000 mm

immediate delivery from stock

Email: [email protected]

office phone::+90 312 382 37 00

office mobile phone: (whatsapp): +90 542 382 37 00

mobile phone: (whatsapp): +90 532 283 01 62

if you need we have also CNC controlled butt welding machines..

The possibility of paying by credit card …

1-)40 mm up to 160 mm MANUEL butt welding machine

2-)From 40 mm to 160 mm SEMI hydraulic butt welding machine

1-Butt Welding Machine body (which connects the pipes) (up to 40 mm to 160 mm, together with all the layouts)

2-trimming unit

3-heater

4-trimming and storage box housing the heater

5-Tool bag

Full sets are shipped.

Delivery immediately from stock … anywhere in Ankara of Turkey sent the shipping charge to be borne by the buyer …

WHY IS THE MACHINE THAT IS THE MOST PREFERRED?

PORTABLE ALL PARTS SEPARATELY, OR ANY THIRD PARTY FOR TWO PIPES TO CARRY OTHER RESOURCES INSTEAD OF WAITING AFTER READING SHOULD STAY SINGLE PEOPLE MOVE EASILY.

EASILY INTO PLACE CAR COVER it can not fit …

3-) From 75 mm to 250 mm FULL HYDRAULIC butt welding machine:

TELEFON:+90 312 382 37 00

FAX:+90 (312) 382 37 77

OFİS GSM: +90 542 382 37 00

GSM: +90 532 283 01 62

Mail: [email protected]

AKANLAR BORU ‘Polietilen Çözüm Merkezi’

4-) From 90 mm to 315 mm FULL HYDRAULIC butt welding machine:

HDPE and PP pipes are used to boil, is fully consistent with all international standards. 32 bar (pn32, ATU) can boil up to the pipe wall thickness, is simple to use and does not require much time to prepare the work. open and can be used indoors, the body is small allows you to work even in narrow channels and strong. Wheel stand, shaving unit, the heating unit is shipped with a hydraulic unit and team where the replacement bolt bag. Pipes allows to make accurate and robust source is completely made a strong grip. 90-110-125-140-160-180-200-225-250-280-300 and boil at 315 mm outer diameter pipe. The total weight of 250 kg. 8KV power generator is sufficient, works with 220 volts, trimming unit 0,75Kw, 3,5Kw heating unit consumes 0,75Kw hydraulic power unit.

We realize not only the technical aspects of the machines will offer in terms of price and ease of job site you will also save you time as well.

5-) From 180 mm to 500 mm FULL HYDRAULIC butt welding machine:

6-) From 315 mm to 630 mm FULL HYDRAULIC butt welding machine:

HDPE and PP pipes are used to boil, is fully consistent with all international standards. 32 bar (pn32, ATU) can boil up to the pipe wall thickness, is simple to use and does not require much time to prepare the work. open and can be used indoors, the body is small allows you to work even in narrow channels and strong. Wheel stand, shaving unit, the heating unit is shipped with a hydraulic unit and team where the replacement bolt bag. Pipes allows to make accurate and robust source is completely made a strong grip. 90-110-125-140-160-180-200-225-250-280-300 and boil at 315 mm outer diameter pipe. The total weight of 250 kg. 8KV power generator is sufficient, works with 220 volts, trimming unit 0,75Kw, 3,5Kw heating unit consumes 0,75Kw hydraulic power unit.

TELEFON:+90 312 382 37 00

FAX:+90 (312) 382 37 77

OFİS GSM: +90 542 382 37 00

GSM: +90 532 283 01 62

Mail: [email protected]

AKANLAR BORU ‘Polietilen Çözüm Merkezi’

7-) From 500 mm to 800 mm FULL HYDRAULIC butt welding machine:

Especially in large-scale machine heater that live with us the convenience of separating iron from the heated pipe … to HIT to get from hitting the pipe heaters to TAKE OUT … HYDRAULIC Inn! …

8) From 630 mm to 1000 mm FULL HYDRAULIC butt welding machine:

TELEFON:+90 312 382 37 00

FAX:+90 (312) 382 37 77

OFİS GSM: +90 542 382 37 00

GSM: +90 532 283 01 62

Mail: [email protected]

AKANLAR BORU ‘Polietilen Çözüm Merkezi’

9-) From 710 mm to 1200 mm FULL HYDRAULIC butt welding machine:

Pity! Your thermometer and the temperature of the heater contactor problems are now roasting in the hot …

Our difference is not only the technical aspects of the machines in terms of price; Due to the use of force and faults to a minimum in descending site you will also save you both time and work to provide ease of use.

The possibility of paying by credit card …

10-) From 1000 mm to 1600 mm FULL HYDRAULIC butt welding machine:

TELEFON:+90 312 382 37 00

FAX:+90 (312) 382 37 77

OFİS GSM: +90 542 382 37 00

GSM: +90 532 283 01 62

Mail: [email protected]

AKANLAR BORU ‘Polietilen Çözüm Merkezi’

11-) From 1600 mm to 2000 mm FULL HYDRAULIC butt welding machine:

About butt welding machines, please don’t finalize your order without information and price …

We realize not only the technical aspects of the machines will offer in terms of price and ease of job site you will also save you time as well.

Especially in large-scale machine heater that live with us the convenience of separating iron from the heated pipe … to HIT to get from hitting the pipe heaters to TAKE OUT … HYDRAULIC Inn! …

Pity! Your thermometer and the temperature of the heater contactor problems are now roasting in the hot …

Our difference is not only the technical aspects of the machines in terms of price; Due to the use of force and faults to a minimum in descending site you will also save you both time and work to provide ease of use.

The possibility of paying by credit card …

BUTT WELDING APPLICATIONS: Polyethylene (PE), PP and PVDF are the most economical and robust welding methods used for welding of fittings and fittings. Pipe is the kind of welding which is welded together by heating only its own material, no matter how many atmospheric compressive strength. This welding method is very economical because; sleeve, welding rod, etc. does not require anything. Once you get the forehead welding machine, you can combine the pipes with the pipes, the pipes, the fittings, and the fitings with heat dissipation.

Firstly, the pipes to be welded are connected to the side of the machine called the table and the settings are made.

the shaving unit which will correct the curvatures at the end points of the pipes is placed and all surfaces are smoothly shaved.

the shaving tool is removed and the forehead to be welded is cleaned so that the dust is free from dirt,

When the heater is placed in the heater together, the heating

By means of a pressure bonding process, the forehead welding is completed and the required cooling time is expected so that the welding process is done.

In the welding process, you do not need to use any additional cuffs or other materials in each welding place, so you have the opportunity to make the most economical way to make pipelines of many kilometers.

What is the difference between Butt Welding and Electrofusion Welding?

The most important difference between the Butt Weld and Electrofusion welding method is that you have to use additional parts of electrofusion cuffs or electrofusion fittings in each additional part in the electrofusion welding process.

However, in the field, you will encounter different situations such that the welding machine is not able to fit in place of the welding machine; Because the electro-fusion welding machine is given electrical current with the connection of the cables to the ef sleeve, welding process can be made more easily in narrow and difficult areas.

Akanlar Piping is taken from both machines as they are applied to any kind of welding application, where it is possible to get the job done more economically. The work is completed more quickly by using the electrofusion welding machine.

Butt-welding? or Electrofusion welding?

One of the most common questions we encounter is kaynak Butt Weld is better or better source of electrofusion? Olur and it is very good in both sources.

What should be paid attention to?

Good adjustment of the forehead of the pipes

Pipe trimming operation as required

To clean the surfaces to be welded with the appropriate substance in the best way

To make pressurized and free heating operation of heater with heater and conditions

To combine the technique with appropriate pressure and time

And as long as the required cooling time is adhered to, the bushing welding method is a truly robust and economical welding method preferred in the manually and visually controlled pressure pipes.

TELEFON:+90 312 382 37 00

FAX:+90 (312) 382 37 77

OFİS GSM: +90 542 382 37 00

GSM: +90 532 283 01 62

Mail: [email protected]

AKANLAR BORU ‘Polietilen Çözüm Merkezi’

Bir önceki yazımız olan Elektro fuzyon kaynak başlıklı makalemizde EF KAYNAK, ef kaynak makinası ve elektrofizyon kaynak hakkında bilgiler verilmektedir.